Why do CleanerVinyl ultrasonic record cleaning systems not use large spacers with O-rings for protecting the labels?

|

Why do CleanerVinyl ultrasonic record cleaning systems not use large spacers with O-rings for protecting the labels?

- Large spacers with O-rings are not necessary. The surface tension of the cleaning fluid keeps it on the vinyl surface.

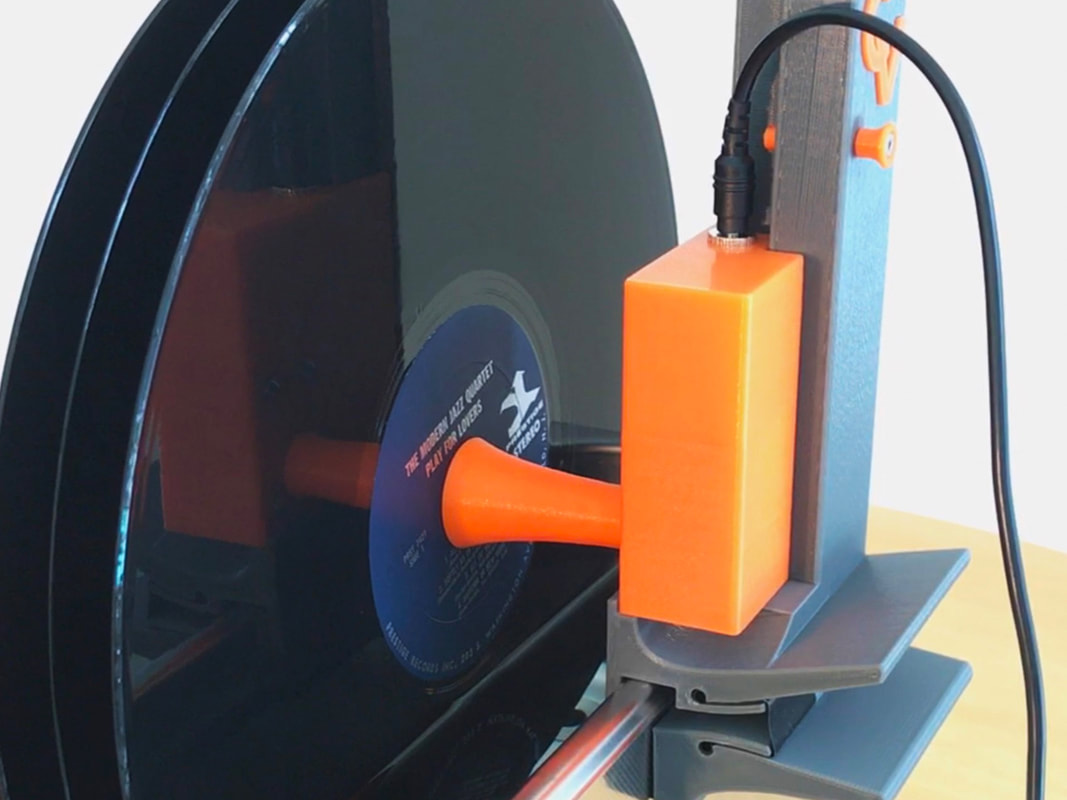

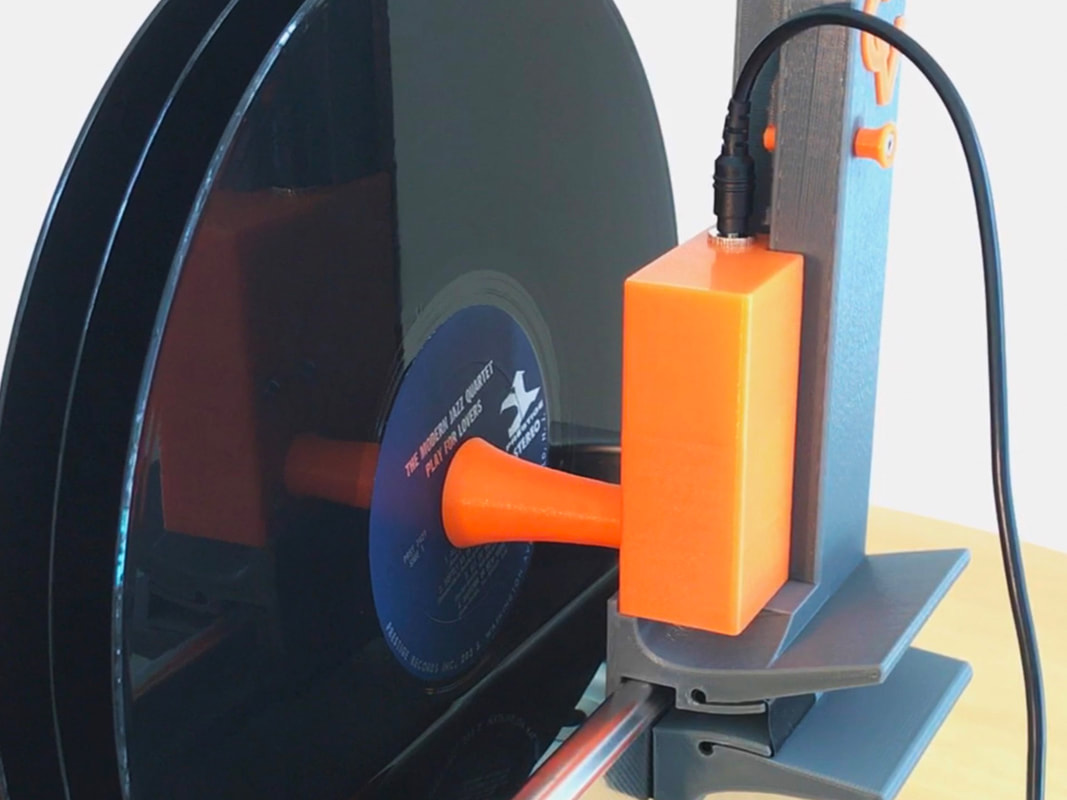

- This is shown in the picture below. In this demonstration with the CleanerVinyl One System the fluid level in the cleaner was adjusted to be about 1/4 inch (~6 mm) below the labels.

- It is obvious that the fluid films stays away from the labels as they rotate through the air outside the cleaning fluid.

- Use of a drying fan further reduces the risk of wetting the labels since the records will never be handled in wet condition: Simply lift the records into the drying position, or drain the tank, while the records spin. Then turn on the fan. About 25 min later the records will be dry and can be re-sleeved.