We often get the question: "What is the best ultrasonic frequency for vinyl record cleaning?".

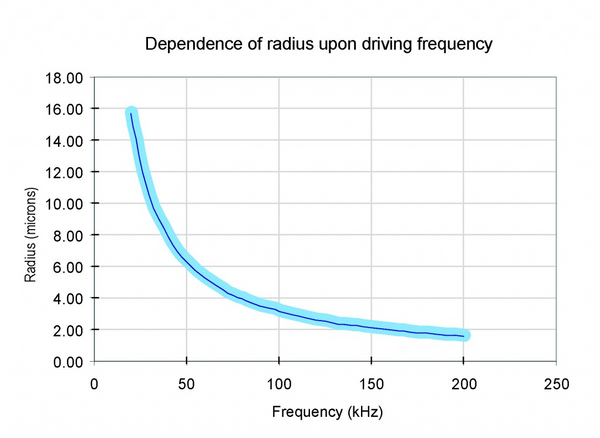

As it is often the case in life, the answer is not totally straight forward. Generally, higher frequencies generate smaller but more cavitation bubbles, while lower frequencies cause fewer but larger bubbles. Furthermore, large bubbles contain more energy that is released during cavitation than smaller bubbles.

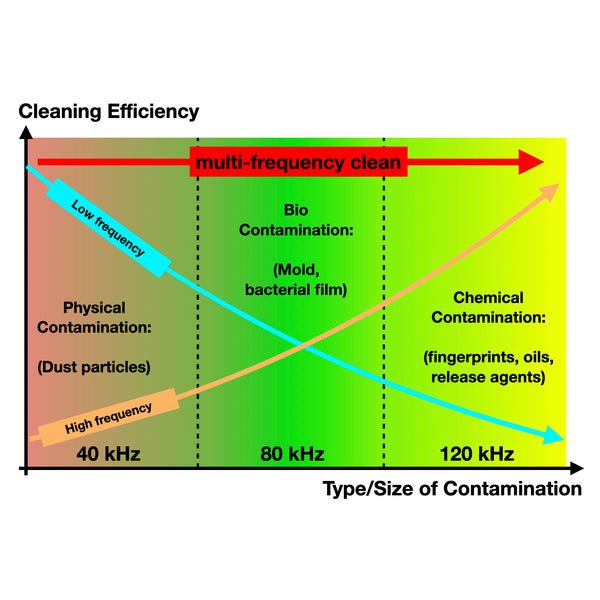

This has the consequence that higher frequencies generally are better at getting into small features during the smaller size of the bubbles and that they clean more gentle and homogenously. This is great for removal of molecular films like chemical and bio contamination. Examples being pressing release agents or mold.

We often get the question: "What is the best ultrasonic frequency for vinyl record cleaning?".

As it is often the case in life, the answer is not totally straight forward. Generally, higher frequencies generate smaller but more cavitation bubbles, while lower frequencies cause fewer but larger bubbles. Furthermore, large bubbles contain more energy that is released during cavitation than smaller bubbles.

This has the consequence that higher frequencies generally are better at getting into small features during the smaller size of the bubbles and that they clean more gentle and homogenously. This is great for removal of molecular films like chemical and bio contamination. Examples being pressing release agents or mold.

Conversely, lower frequencies are better at the removal of coarse dirt due to the higher energy blasts from their bigger bubbles. But the clean is less homogenous and less detailed.

This means that the best approach is to use a multi-frequency cleaner that can cycle through several frequencies. Starting at a low frequency the coarse dirt is removed opening up the surface for the higher frequencies that then can do the detail work of cleaning smaller particles and molecular films while getting deep into the grooves.

Alternatively, a multi-bath approach can be used where the record stack is first cleaned in a standard 40 kHz cleaner, followed by a run in a 132 kHz high-frequency cleaner. While needing a larger footprint and more work, this approach has the advantage that the coarse dirt is removed in a separate tank further limiting redepositon of dirt. This approach is easily done using our Pro and ProXL Systems whose motor units can be put directly on the rim of a cleaner. The motor unit is simply moved while rotating from one cleaner to the other.

Conversely, lower frequencies are better at the removal of coarse dirt due to the higher energy blasts from their bigger bubbles. But the clean is less homogenous and less detailed.

This means that the best approach is to use a multi-frequency cleaner that can cycle through several frequencies. Starting at a low frequency the coarse dirt is removed opening up the surface for the higher frequencies that then can do the detail work of cleaning smaller particles and molecular films while getting deep into the grooves.

Alternatively, a multi-bath approach can be used where the record stack is first cleaned in a standard 40 kHz cleaner, followed by a run in a 132 kHz high-frequency cleaner. While needing a larger footprint and more work, this approach has the advantage that the coarse dirt is removed in a separate tank further limiting redepositon of dirt. This approach is easily done using our Pro and ProXL Systems whose motor units can be put directly on the rim of a cleaner. The motor unit is simply moved while rotating from one cleaner to the other.

Bubble size vs. frequency graph from:https://techblog.ctgclean.com/blog/ultrsonics-number-and-size-of-cavitation-bubbles/